Kesinlikle soğuk çekilmiş dikişsiz karbonlu özel çelik boru SA192 OD 38mm kazan için

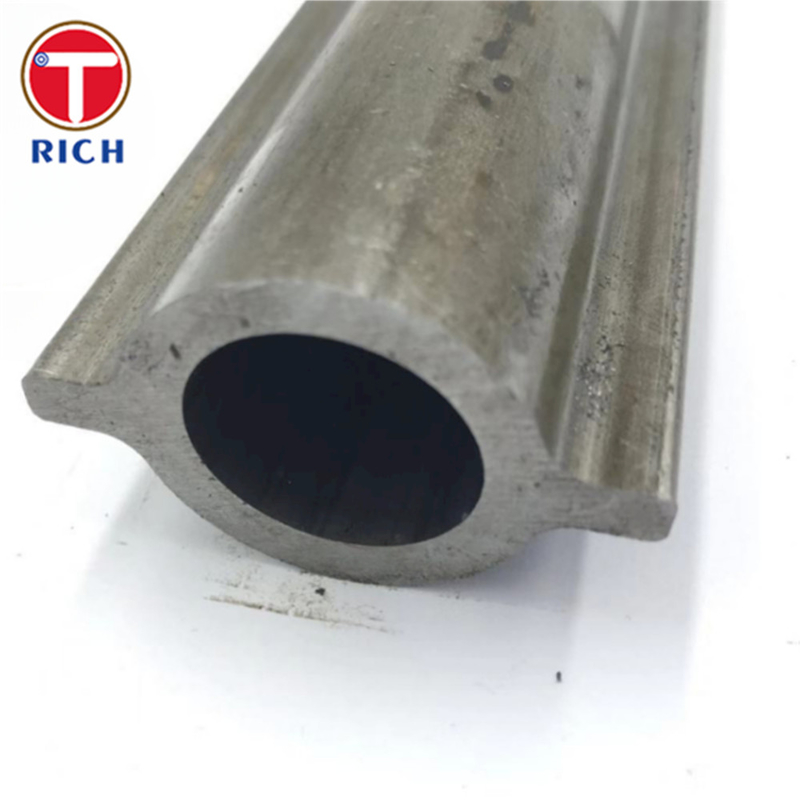

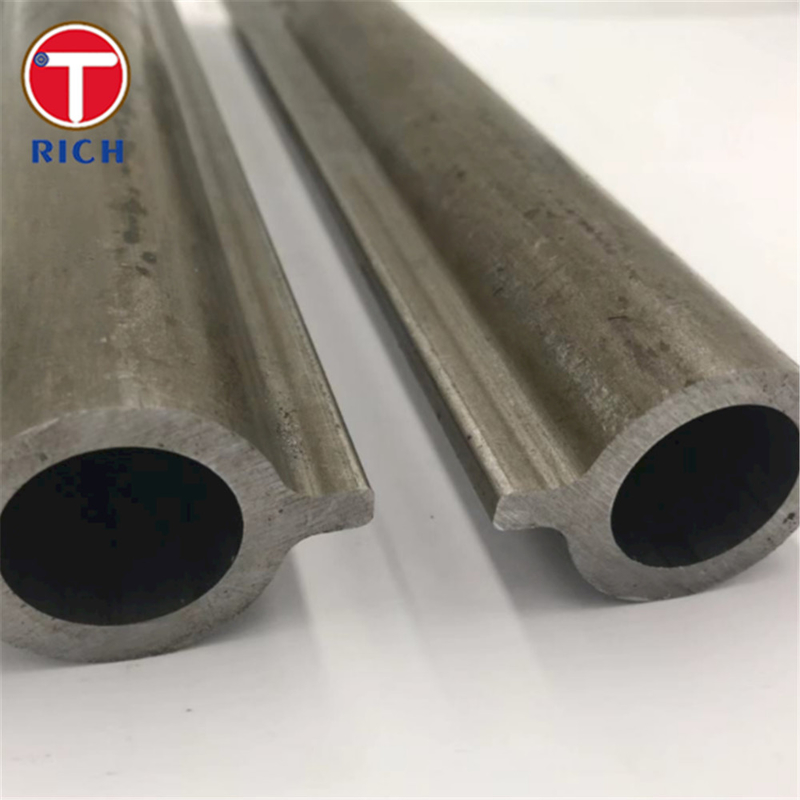

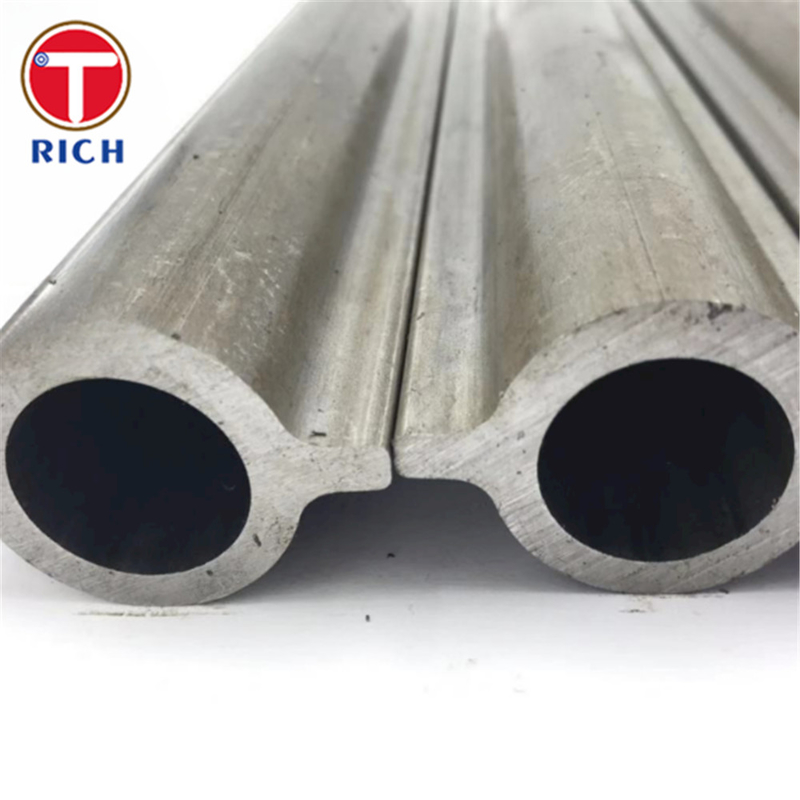

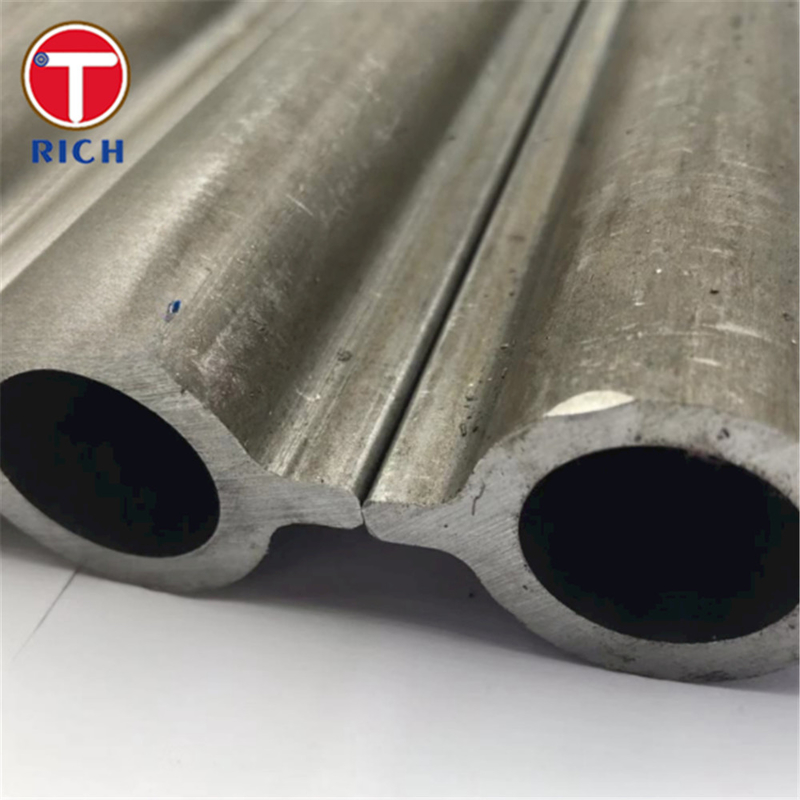

Özel Çelikler Dikişsiz Omega tüpü, karbon ve alaşımlı çelikten yapılır, ekstrüzyon ve soğuk çekim yoluyla üretilir, Omega tüpleri kazanlarda ve süper ısıtıcılarda kullanılır.Daha iyi ısıtma verimliliği için.

| Ürün bilgileri: | |

| Malzeme: | SAE1010, SAE1020, SAE1035, SAE1045, ST37.0, ST44, ST52, E235, E355 |

| Sınıf: | BS, JIS, GB, DIN, ASTM, API, |

| Şekil: | Omega. |

| Duvar kalınlığı: | 0.5-50mm |

| Uzunluk: | 12 metreye kadar veya müşterinin talebine göre. |

| Dış çapı: | Yuvarlak: 5-420mm |

| | Diametre ve duvar kalınlığı müşterinin isteğine göre olabilir. |

| | |

| Teknoloji: | Soğuk çekim/soğuk yuvarlama |

| Yüzey işlemi: | Renkli, galvanizli veya müşteriye göre yağlanmış |

| Uygulama: | Aydınlatma, mobilya, tıbbi ekipman |

| Doğum yeri: | Çin |

| Uygulama | Mekanik yapı, Karbon basınçlı makineler vb. |

| Nakliye ve Ödeme: | |

| Paketleme: | Toplu olarak veya müşterinin gereksinimlerine göre |

| MOQ: | 5 MT |

| Teslimat şartları: | FOB Şangay |

| Şartlar: | T/T, %30 avans, B/L kopyasına karşı bakiye ödenir |

| Teslim süresi: | Ödemeyi aldıktan sonraki 25-40 gün içinde

|

| Malzeme ve Standart |

| Ürün | Çin Standartı | Amerikan Standartı | Alman Standartı |

| 1) | 10# | A53A | St37 | |

| A106A | St37-2 | DIN17175 |

| A179C | St35.8 | DIN1629 |

| 2) | 20# | ASTMA106-B | St45-8 | DIN17175 |

| ASTMA53-B | St42-2 | DIN1626 |

| ASTMA178-C | St45-4 | DIN1629 |

| 3) | 45# | ASTMA1045 | CK45 | |

| 4) | 16Mn | ASTMA210-C | St52 | DIN1629/3 |

| St52.4 | DIN1629/4 |

| 5) | 1010,1020,4130,4140 | ASTM A519 | | |

Dikişsiz soğuk işlenmiş borular

Fabrikamızda mevcut olan dikişsiz soğuk işlenmiş borular özel olarak üretilir, ham form katı çubuktan oluşturulur ve gövde boşluğuna dönüştürmek için delinir.Yerel normalleştirme işlemimiz soğuk çalışma için uygun borular üretir, ve bir sülfürik asit temizleme, soğuk duruma yıkamak ve yağlama banyosu sonra, belirtilen malzemeler karbid matros ile bir mandrel çekme tezgahı kullanılarak çekilir.ve duvar kalınlıkları yüksek germe özellikleri ile sonuçlanan gerekli boyutlara düşürülür, boyut hassasiyeti, mikro yapı tekdüzeliği ve mükemmel yüzey kalitesi. Tüpler 1020, 1026, 1030, 4130,Diğerleri arasında 4140 ve 4150.

Deneyimli boru üretim sürecimiz, kritik uygulamalar için müşteri tarafından belirlenen bileşenleri üretmek için uyarlanmış ve değiştirilmiştir.Parçalar gerginlikten kurtulur, diğerleri söndürülür ve ısıtılır, ardından son derece düz borular ve boru uçları için döner düzleştirme ile tam 90 ° kareye kesilir.Parçalar kabuktan çıkarılır ve pas önleyici bir işlemle kaplanır. En yüksek kalite ve doğruluk seviyelerini sağlamak için süreçte ve üretim sonrasında kapsamlı test yöntemleri kullanılır.Çevrimsel akım testi dahil, % 100 boyut testleri, düzlük ve kozmetik değerlendirmeler için.

Teslimat şartları

1. BK (+C)

Son soğuk şekillendirme işleminden sonra ısı işlemi yapılmadı.

2BKW (+LC)

Son ısı işleminden sonra hafif bir bitirme geçişi vardır (soğuk çizim)

3. BKS (+SR)

Son soğuk şekillendirme işleminden sonra tüpler gerginliği azaltmak için küvetlenir.

4. GBK (+A)

Son soğuk şekillendirme işleminden sonra borular kontrol edilen bir atmosferde kızartılır.

5. NBK (+N)

Son soğuk şekillendirme işleminden sonra tüpler üst dönüşümün üzerinde küvetlenir

Kontrolü altındaki bir ortamda.

6.SR

Stresten kurtulma süreci

7.Q+T

HRC30-HRC45'e kadar söndürme ve sertleştirme

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!